3D PRINTING SUSTAINS CREATIVITY, EFFICIENCY FOR LUXURY JEWELRY MANUFACTURER

October 23, 2025

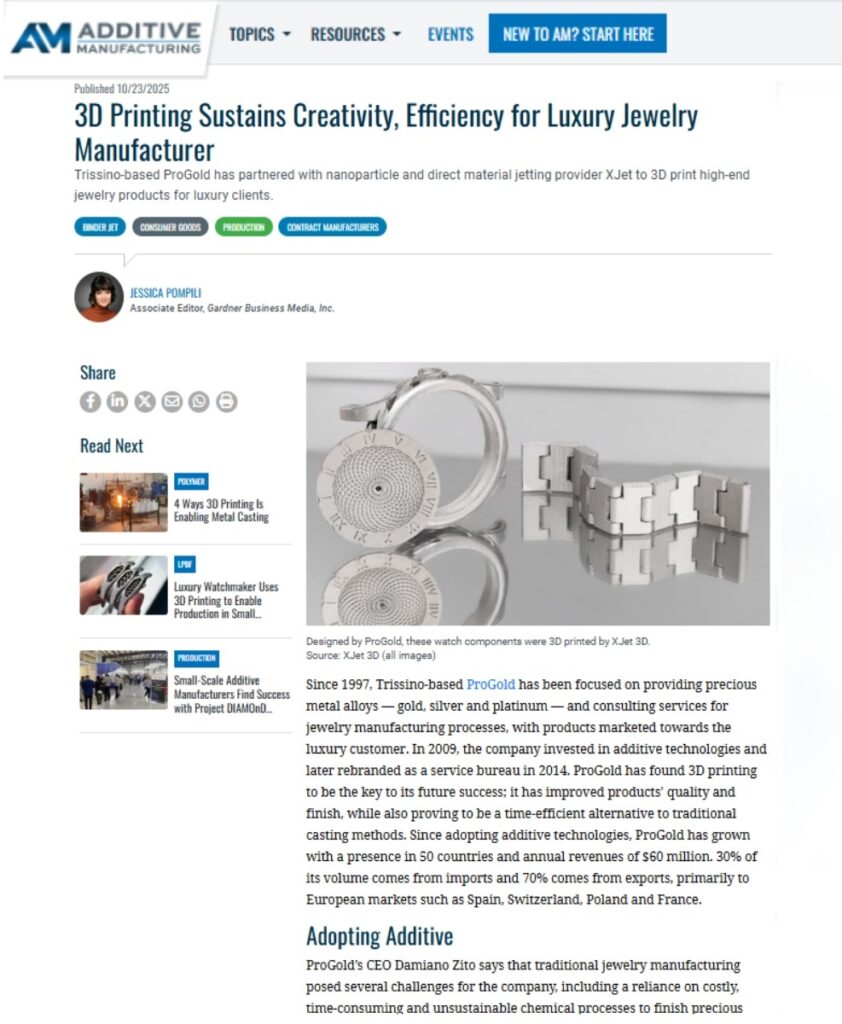

Since 1997, Trissino-based ProGold has been focused on providing precious metal alloys — gold, silver and platinum — and consulting services for jewelry manufacturing processes, with products marketed towards the luxury customer. In 2009, the company invested in additive technologies and later rebranded as a service bureau in 2014. ProGold has found 3D printing to be the key to its future success; it has improved products’ quality and finish, while also proving to be a time-efficient alternative to traditional casting methods. Since adopting additive technologies, ProGold has grown with a presence in 50 countries and annual revenues of $60 million. 30% of its volume comes from imports and 70% comes from exports, primarily to European markets such as Spain, Switzerland, Poland and France.

Adopting Additive

ProGold’s CEO Damiano Zito says that traditional jewelry manufacturing posed several challenges for the company, including a reliance on costly, time-consuming and unsustainable chemical processes to finish precious metals like gold. Investment casting, with its multiple phases (up to nine compared to additive’s two to four), caused further inefficiency for ProGold.

More News