MATERIALS

XJet offers material portfolio in technical metals, precious metals and ceramics, serving for a variety of industries and sectors.

MATERIALS

XJet offers material portfolio that are the result in technical metals, precious metals and ceramics, serving for a variety of industries and sectors.

Main Features

- High durability and density

- Workability for intricate details and various finishes

- Full design freedom for previously-impossible inner cavities and assembly

- 0 inventory, negligible material waste

Common Applications

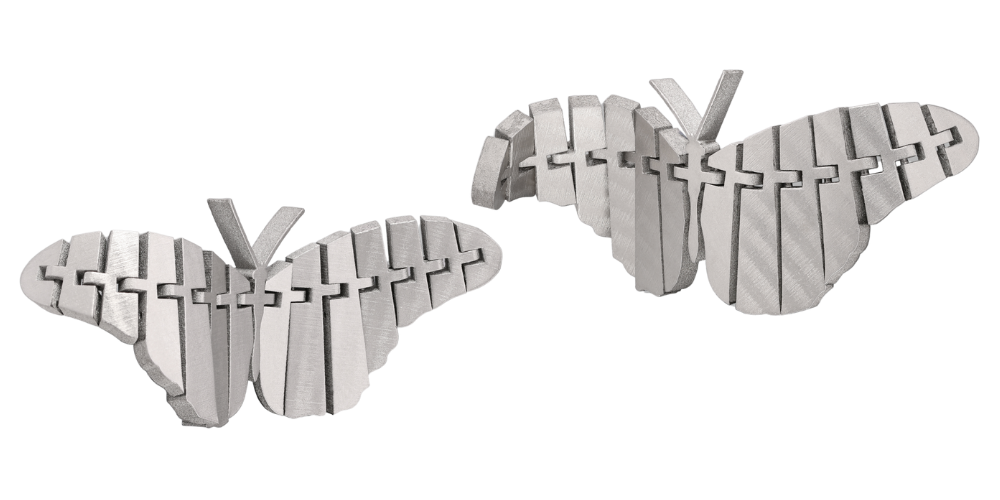

- Luxury Jewelry

- Premium Timepieces

Industries

Jewelry and fashion accessories

Main Features

- 0 inventory, negligible material waste

- Full design freedom for previously-impossible inner cavities and assembly

- Workability for intricate details and various finishes

Common Applications

- Luxury Jewelry

- Premium Timepieces

Industries

Jewelry

Watch making

Main Features

- High Strength and Hardness

- Corrosion Resistance

- Superior Performance at High Temperatures

- Aging Treatment Flexibility

Common Applications

- Medical Instrument

- Aerospace Components

- Laboratory Equipment

- Marine Applications

- Machinery Components

- Chemical and Petrochemical Processing

Industries

Industrial

Machinery

Medical

Surgical Forceps

Main Features

- Corrosion Resistance

- Superior Performance at Both High and Low Temperatures

- High Strength

- Heat and Corrosion Resistance

Common Applications

- Food Processing

- Laboratory Equipment

- Petroleum Refining

- Medical Devices

- Marine Applications

- Power Generation

- Water Treatment

- Chemical and Petrochemical Processing

Industries

Industrial

Advanced Industrial

Consumer

Luxury Goods

Medical

Surgery

Main Features

- One of the strongest and toughest fine ceramic materials

- Outstanding heat insulation - thermal conductivity is less than 1/10 of other ceramics

Common Applications

- Bearing balls

- Dental Applications

- Chemistry Lab Applications

- Mortars and Pestle Grinding Jars and Grinding Balls

- Machinery Components

- Valve and pump parts

Industries

Industrial

Advanced Industrial

Consumer

Wearables

Medical

Dental

Main Features

- One of the strongest and toughest fine ceramic materials

- Outstanding heat insulation - thermal conductivity is less than 1/10 of other ceramics

Common Applications

- Bearing balls

- Dental Applications

- Chemistry Lab Applications

- Mortars and Pestle Grinding Jars and Grinding Balls

- Machinery Components

- Valve and pump parts

Industries

Industrial

Advanced Industrial

Consumer

Wearables

Medical

Dental

Materials for Ceramic 1400C System

ALUMINA – ALUMINUM OXIDE (AI203)

For Ceramic Parts

Main Features

- High Electrical Insulation

- High Strength

- The Most Common Technical Ceramic Material

- Wear Resistance and Thermal Conductivity

- Heat and Corrosion Resistance

Common Applications

- Thermocouple Sheaths

- Wire and Thread Guides

- Wear-Resistant Pump Impellers

- Piping Components, Nozzles and Valves

- Electrical Insulators

- Machining and Cutting Tools

Industries

Industrial

Advanced Industrial

Consumer

Wearables

Medical

Dental

Main Features

- High Electrical Insulation

- High Strength

- The Most Common Technical Ceramic Material

- Wear Resistance and Thermal Conductivity

- Heat and Corrosion Resistance

Common Applications

- Thermocouple Sheaths

- Wire and Thread Guides

- Wear-Resistant Pump Impellers

- Piping Components, Nozzles and Valves

- Electrical Insulators

- Machining and Cutting Tools

Industries

Industrial

Advanced Industrial

Consumer

Wearables

Medical

Dental

Main Features

- Corrosion Resistance

- Superior Performance at Both High and Low Temperatures

- High Strength

- Heat and Corrosion Resistance

Common Applications

- Food Processing

- Laboratory Equipment

- Petroleum Refining

- Medical Devices

- Marine Applications

- Power Generation

- Water Treatment

- Chemical and Petrochemical Processing

Industries

Industrial

Advanced Industrial

Consumer

Luxury Goods

Medical

Surgery

Main Features

- The AM industry’s Only Support Material That Can Be Rinsed Away Hands-Free

- Fully Automated Support Removal Process

How Does It Work?

- Soluble Support is Jetted simultaneously with metal or ceramic build material, creates temporary support structures, required for additive manufacturing of various parts

Main Benefits

- Significant Cost- Efficiency

- Shortens Post Processing

Main Features

- The AM industry’s Only Support Material That Can Be Rinsed Away Hands-Free

- Fully Automated Support Removal Process

How Does It Work?

- Soluble Support is Jetted simultaneously with metal or ceramic build material, creates temporary support structures, required for additive manufacturing of various parts

Main Benefits

- Significant Cost- Efficiency

- Shortens Post Processing

Download the Material Portfolio Brochure

Just a few clicks, we will support you with the selection of your high-performance production.